New Manufacturing, Higher Quality

A Turning Point in 2022

A Strategic Shift Toward Independent Development

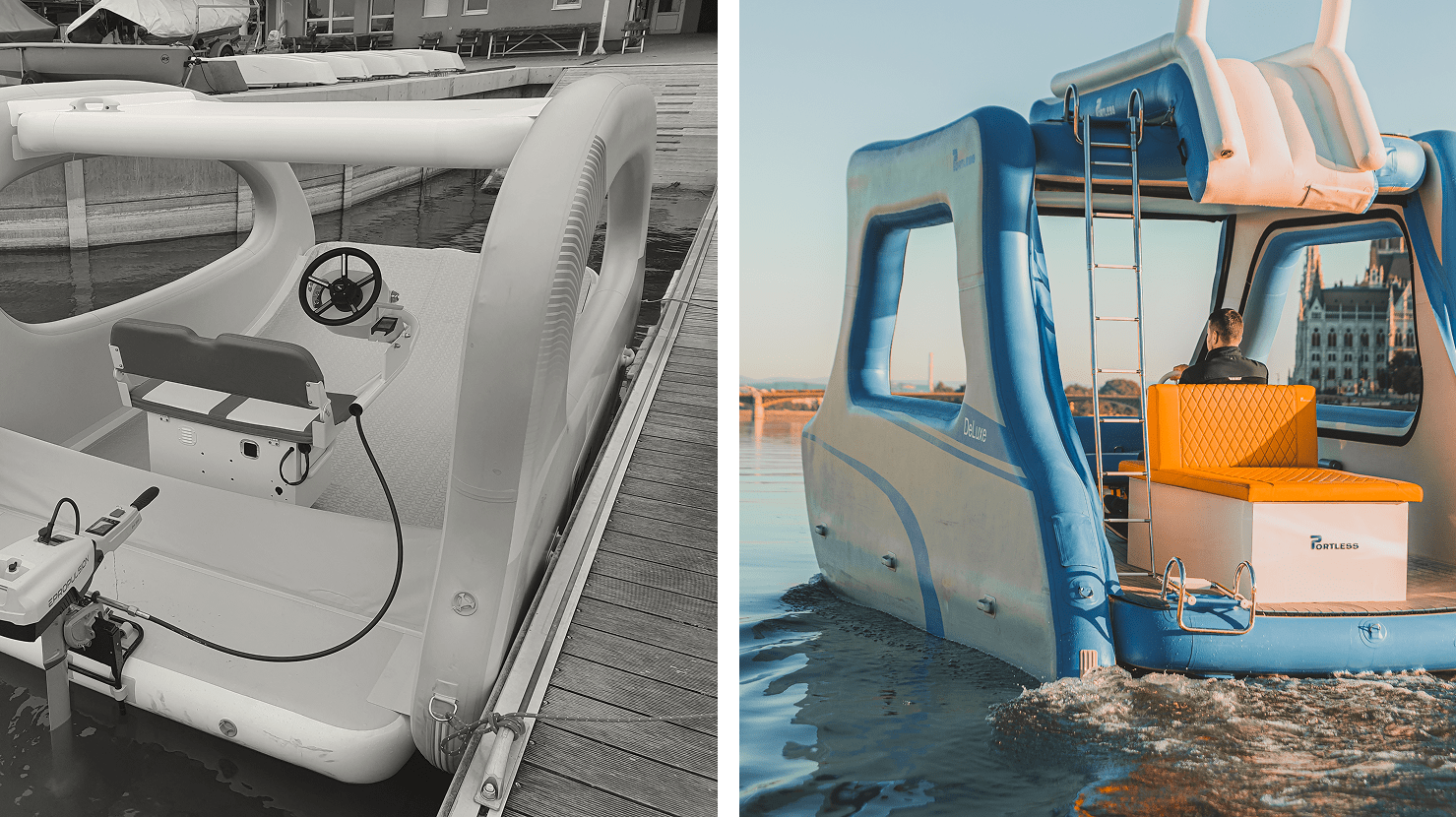

By 2022, the Portless team decided to begin fully independent product development, abandoning the original amoeba-shaped models, as their performance, usability, and safety were highly limited, especially in rough or stormy conditions.

This marked the moment when the first design sketches were created, with the involvement of a naval engineer, giving shape to the initial concepts and forms.

The two primary design principles were:

- Safety

- Practical usability

To achieve these goals, it was not enough to redesign the shape alone—the structural components themselves had to be reengineered. Previously, many elements were derived from modified pre-manufactured parts, which proved insufficient both functionally and aesthetically.

This development phase fundamentally transformed the Portless product line at the material level.

Advanced Materials – A New Structural Foundation

The new boats were manufactured using double-wall drop-stitch material, which resulted in a significant increase in durability and expected service life compared to the earlier amoeba-shaped predecessors.

But what challenges did this impose on our engineering team and manufacturing units? Join us—and discover the answer.

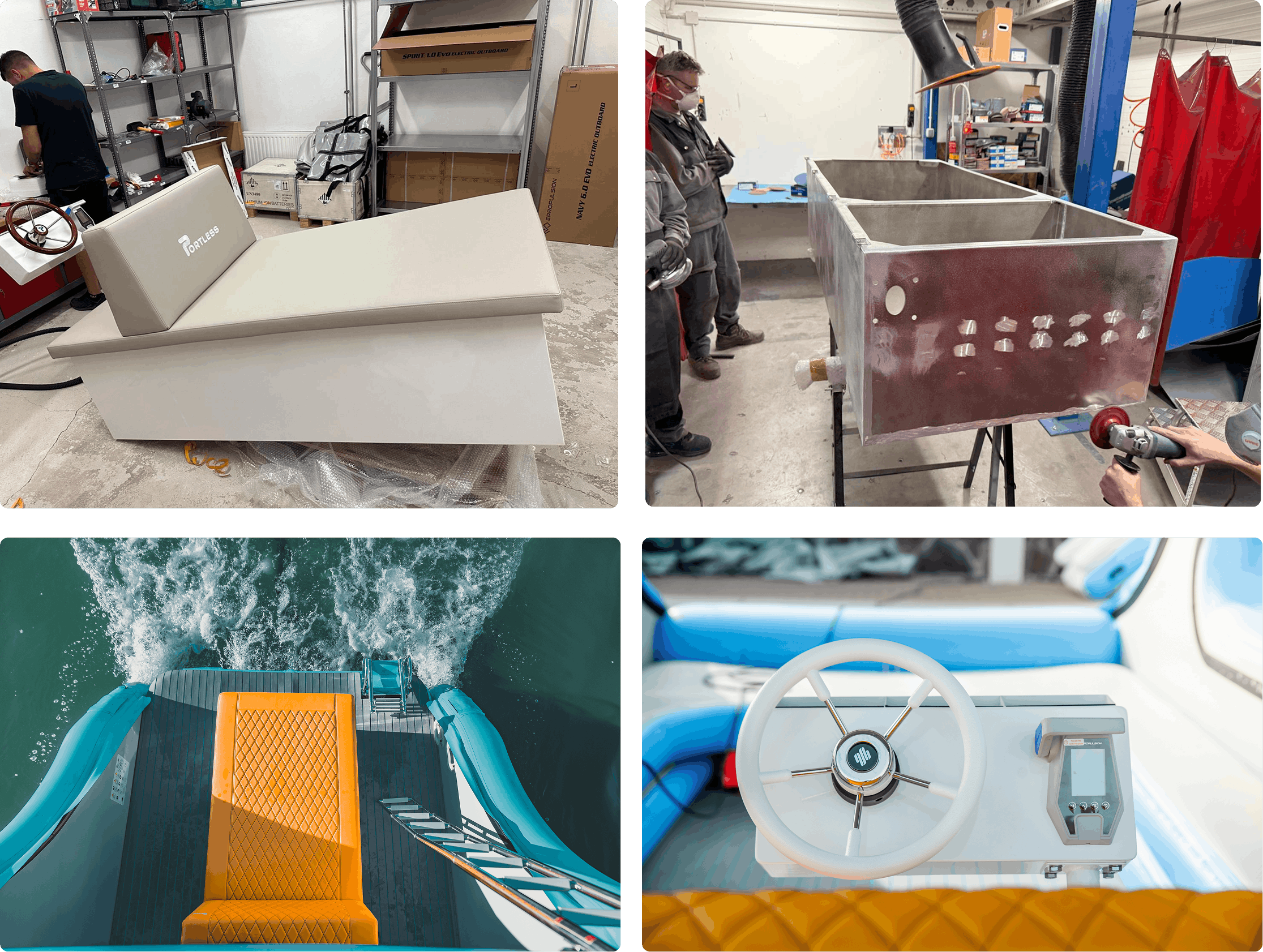

The Helm Station – The Heart of Premium Portless Boats

The core of our premium models lies within the helm station, which houses the entire propulsion system.

Key features include:

- Construction from marine-grade stainless aluminum, eliminating concerns about corrosion

- An UV-, water-, and heat-resistant upholstered surface on the upper section, allowing for safe and comfortable sunbathing

For the first time worldwide, the outboard engine was integrated inside the hull, combining the advantages of outboard and inboard engines.

As a result, the rear platform remains completely unobstructed, enabling:

- Safe leg-dangling

- Reduced accident risk

Hull Manufacturing – From Gluing to Welding Technology

The hull manufacturing process was completely redefined. Since 2022, Portless hulls have no longer relied on adhesive bonding, but instead use welding technology.

The advantages of welding include:

- Significantly increased durability

- Perfectly aligned surfaces, eliminating leaks caused by adhesive failure

- Superior aesthetics, as the hull remains free from the characteristic yellow stains caused by PVC glue reacting with sunlight

User-Centered Deck Design

Deck-mounted accessories—such as mooring eyes, grab handles, and protective surfaces—are positioned based on direct customer feedback.

The EVA deck surface is attached using Velcro fastening, ensuring:

- Secure footing

- Safe movement on deck, even with wet feet

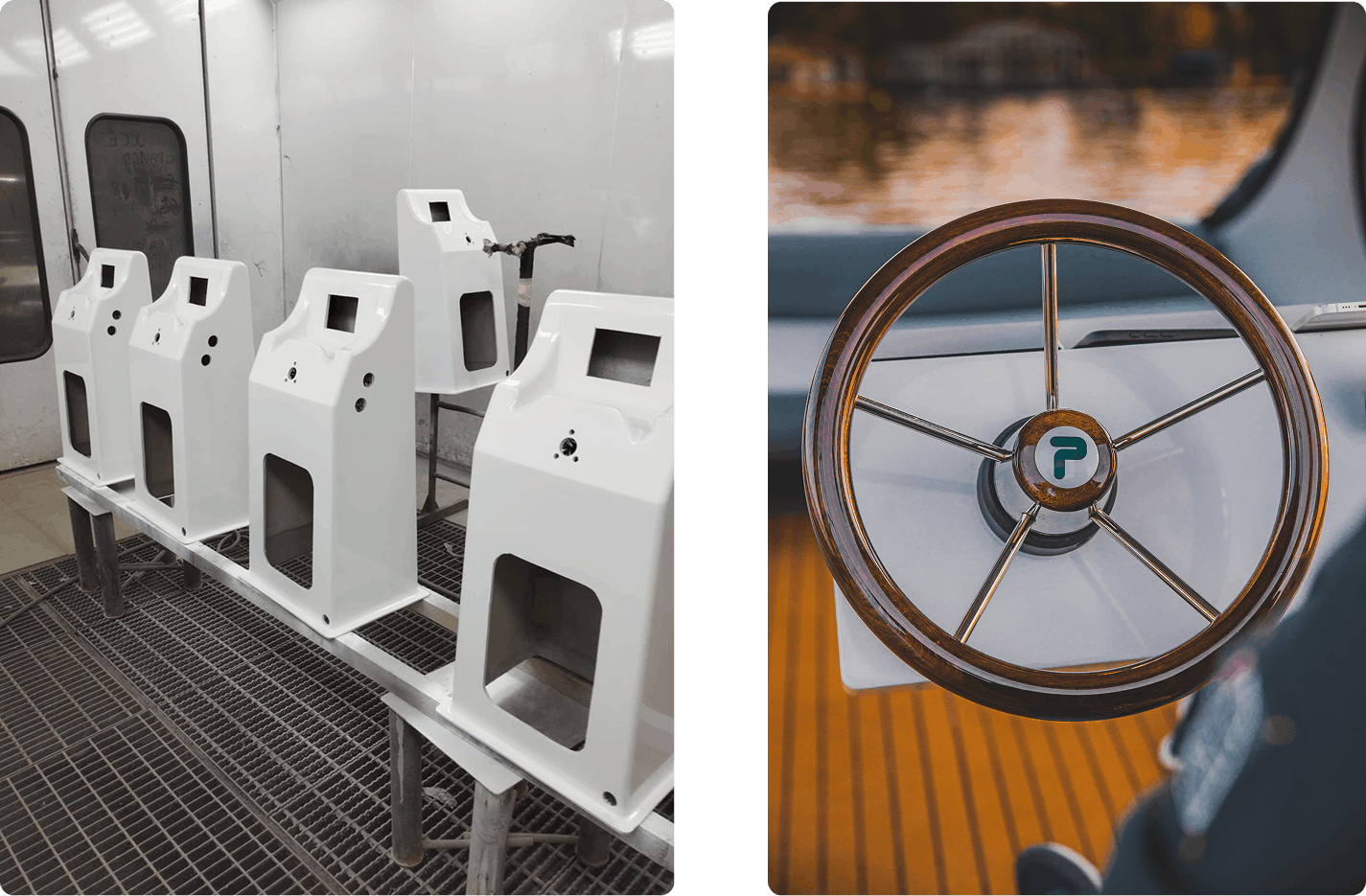

Innovative Helm Mounting for the Trinity Model

The helm station used on the smaller Portless Trinity model was also developed based on customer insights.

Key design objectives included:

- Practical usability

- Visual appeal

- Easy transport and installation

Traditional inflatable boats often rely on PVC plates glued to the hull with protruding bolts, which are dangerous and difficult to transport.

To solve this, the Portless engineering team developed a groundbreaking mounting system, once again first to market, enabling safe, simple, and user-friendly operation.

Custom Accessories Across the Entire Product Range

Every model in the Portless product portfolio is supported by a wide range of custom-developed accessories, including:

- Individually designed stainless chrome ladders

- Engine mounts

- Mooring eyes

- Other small yet critical components

To ensure perfect visual and functional harmony, Portless International Ltd. designs each accessory specifically for its boats, matching the refined expectations of Portless customers.

Logistics, Packaging, and Assembly Support

The process does not end with design, manufacturing, and assembly.

As most customers import their Portless boats (with optional pickup from the Portless International warehouse in Hungary), packaging receives special attention:

- Boats are shipped mounted on pallets

- This allows customers to easily handle and move the shipment upon arrival

For fast and effortless assembly, an expert installation service is available in Europe and the United States, where a professional team assembles the ordered boat on-site.

This service is most commonly used for:

- Pre-assembly

- Larger hull models

- Simultaneous commissioning of multiple boats

For more adventurous owners, detailed user manuals, assembly guides, and instructional videos are provided—allowing a complete setup in as little as 7 minutes.